Setup: VORON v2.4 with SKR v1.3+ Klipper + Octoprint

Make sure to have a Klipper version that supports the „filament_motion_sensor“ ( I had not..)

Upgrade Klipper:

https://www.klipper3d.org/FAQ.html#how-do-i-upgrade-to-the-latest-software

Upgrade SKR v1.3 via USB:

https://www.klipper3d.org/SDCard_Updates.html

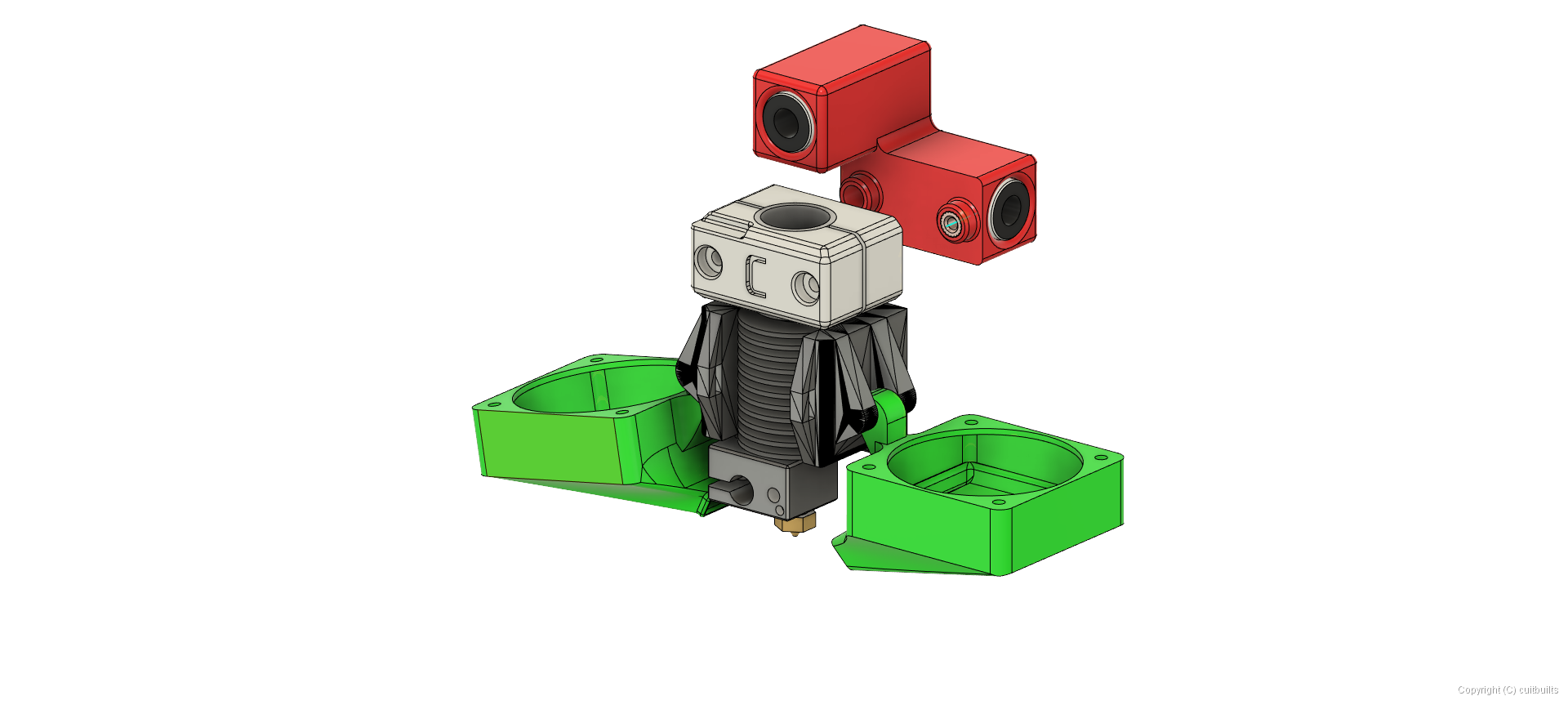

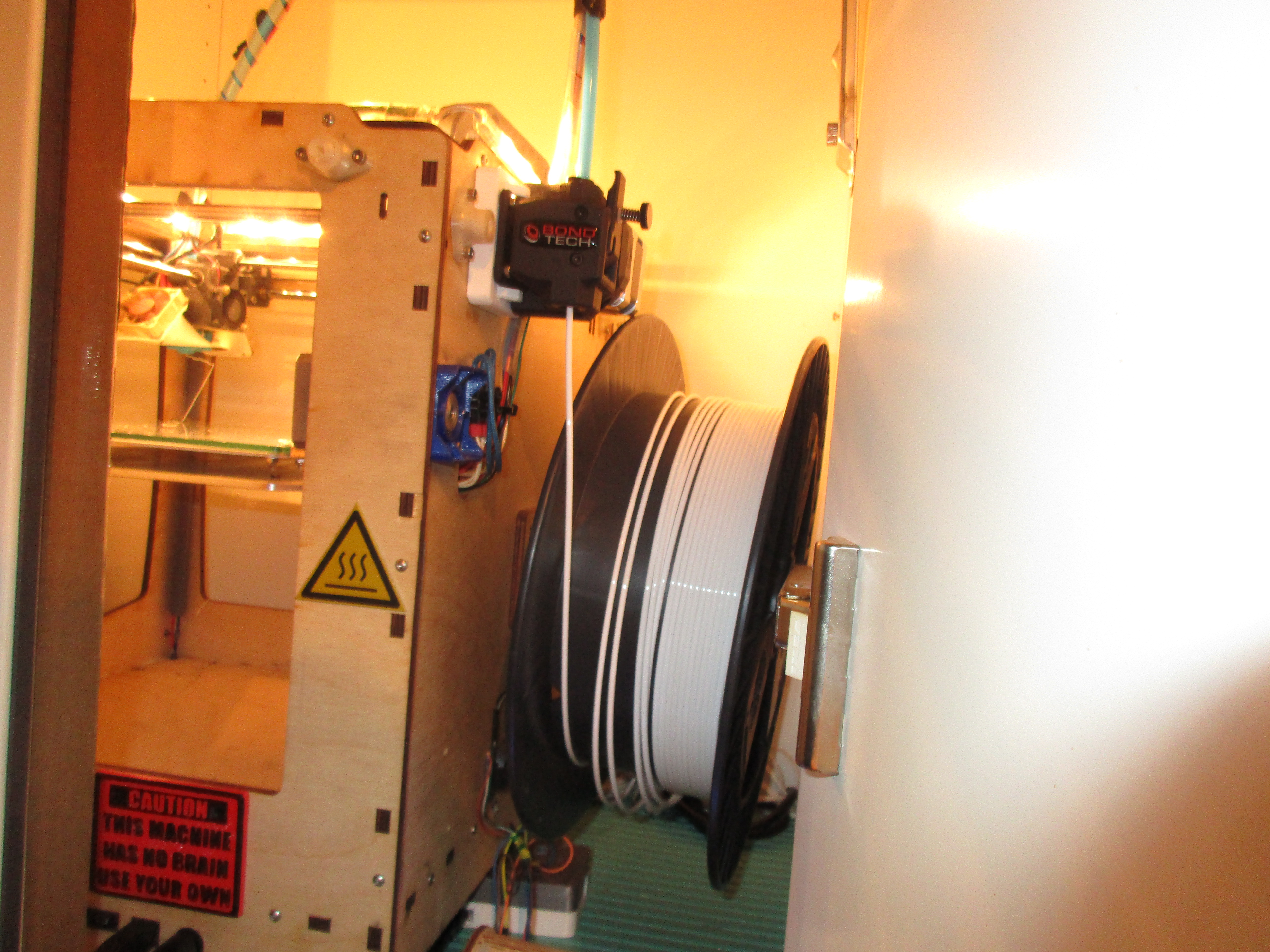

Mounting/ Connecting:

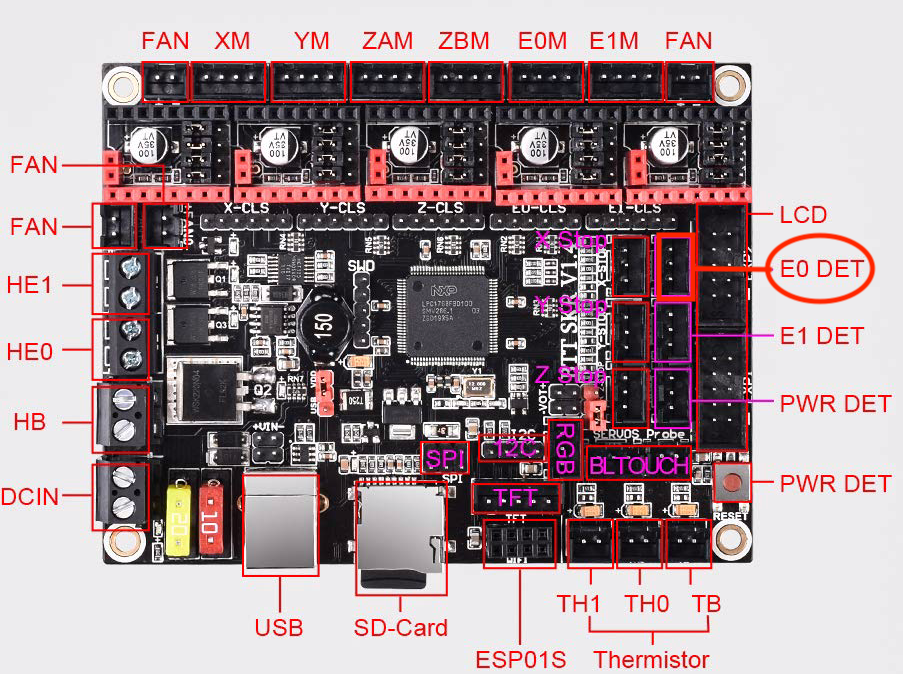

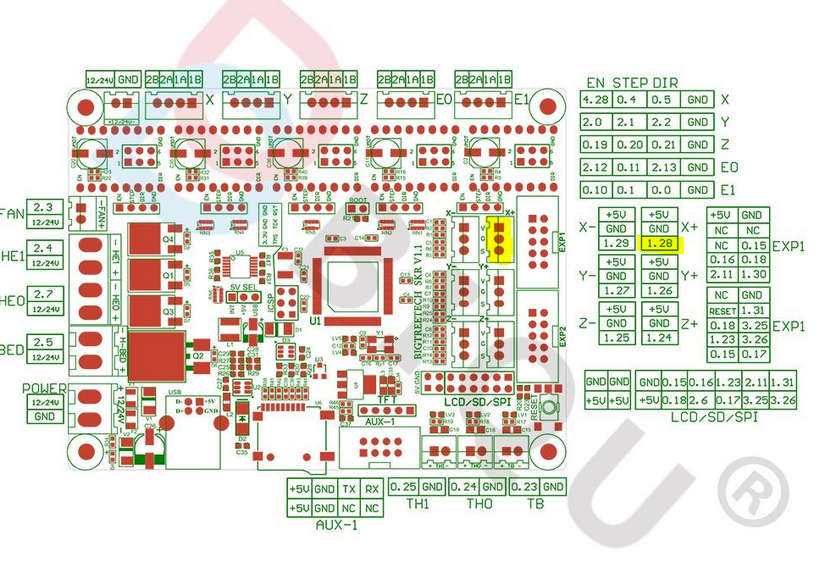

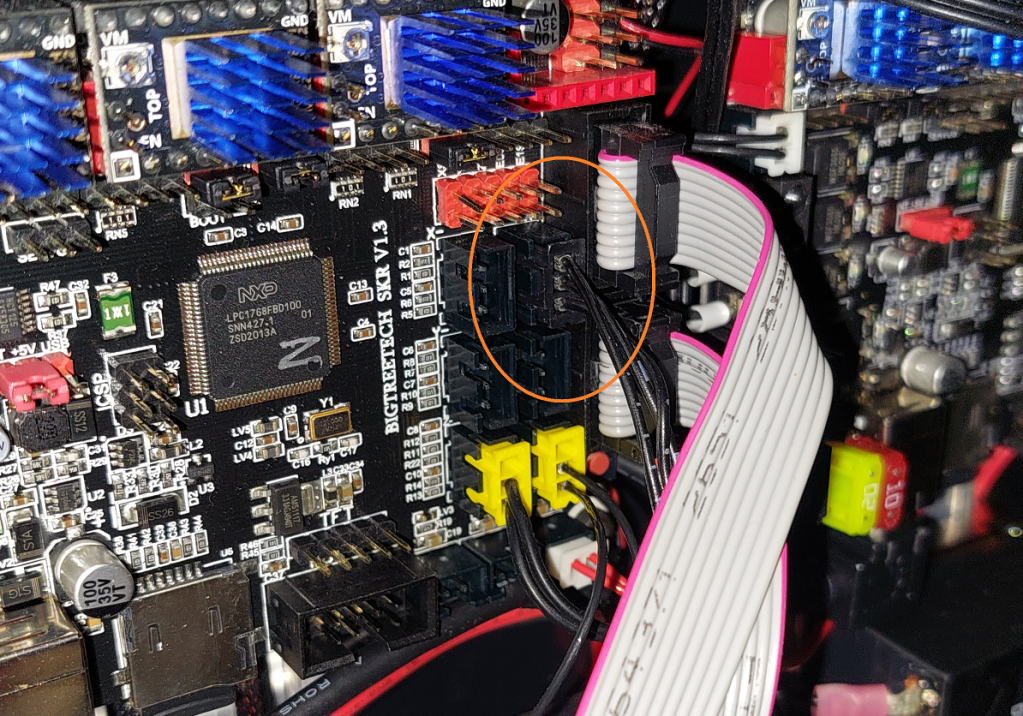

Mount the sensor and connect it to one of your SKR v1.3 boards. Make sure everything is turned off!

I connected mine to the E0 DET on the Z board so the pin is z:P1.28. I had to make sure the Pin is pulled up. Mine config is: „switch_pin: ^z:P1.28″

Software / Klipper:

Update your config like:

[filament_motion_sensor btt_sensor]

detection_length: 7.0

# The minimum length of filament pulled through the sensor to trigger

# a state change on the switch_pin

# Default is 7 mm.

extruder: extruder

# The name of the extruder section this sensor is associated with.

# This parameter must be provided.

switch_pin: YOURPINHERE

# The pin on which the switch is connected. This parameter must be

# provided.

pause_on_runout: True

# When set to True, a PAUSE will execute immediately after a runout

# is detected. Note that if pause_on_runout is False and the

# runout_gcode is omitted then runout detection is disabled. Default

# is True.

runout_gcode:

M117 Filament out

# A list of G-Code commands to execute after a filament runout is

# detected. See docs/Command_Templates.md for G-Code format. If

# pause_on_runout is set to True this G-Code will run after the

# PAUSE is complete. The default is not to run any G-Code commands.

#insert_gcode:

# A list of G-Code commands to execute after a filament insert is

# detected. See docs/Command_Templates.md for G-Code format. The

# default is not to run any G-Code commands, which disables insert

# detection.

#event_delay: 3.0

# The minimum amount of time in seconds to delay between events.

# Events triggered during this time period will be silently

# ignored. The default is 3 seconds.

#pause_delay: 0.5

# The amount of time to delay, in seconds, between the pause command

# dispatch and execution of the runout_gcode. It may be useful to

# increase this delay if OctoPrint exhibits strange pause behavior.

# Default is 0.5 seconds.https://www.klipper3d.org/Config_Reference.html#filament_motion_sensor

Enable the sensor:

SET_FILAMENT_SENSOR SENSOR=btt_sensor ENABLE=1

You can check whether the sensor ist working with but only reliable when a print is running:

QUERY_FILAMENT_SENSOR SENSOR=btt_sensorDisable the sensor:

SET_FILAMENT_SENSOR SENSOR=btt_sensor ENABLE=0

Macros

Best macros i found:

https://github.com/AndrewEllis93/Print-Tuning-Guide/blob/main/articles/useful_macros.md